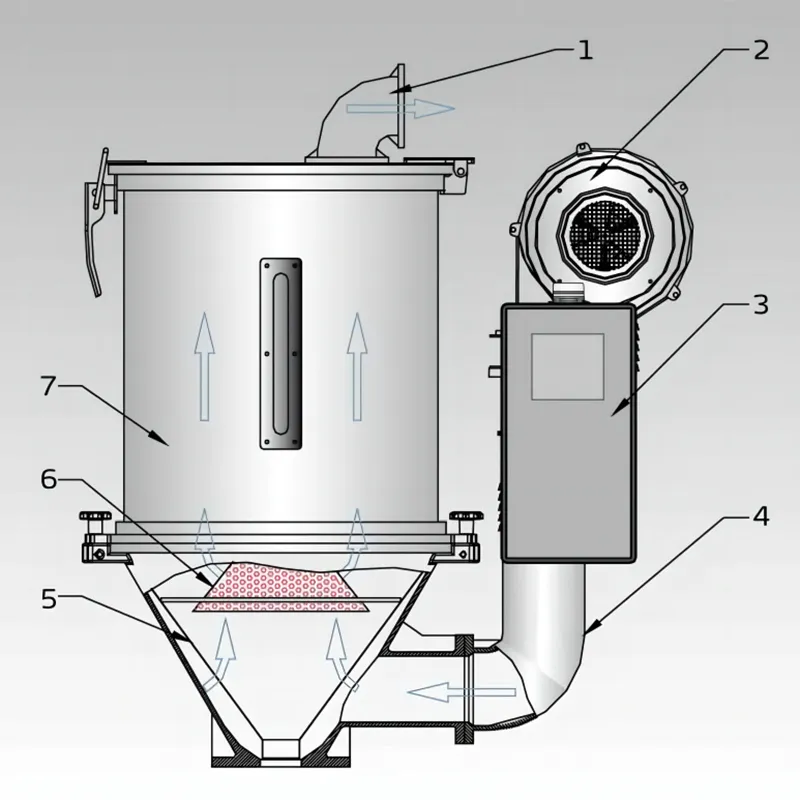

Standard Hopper Dryer

Drying hopper for processing raw plastic granules

Designed to dry a variety of non-hygroscopic plastics such as PS, PP, and ABS, these hopper dryers reach a maximum drying temperature of 160°C. They feature several optional enhancements that improve functionality. These include systems for recycling hot air and filtering out impurities like iron particles from raw materials. Additionally, these dryers can be fitted with a stand for convenient floor installation.

- Constructed with stainless steel in areas that contact materials to prevent contamination.

- Equipped with safety features that cut off power to the heater if the drying temperature exceeds the preset limit, accompanied by a flashing alarm for immediate notification.

- Uses heat-insulated blower to increase the longevity of the unit.

- Includes a one-week timer and options for intermittent running, enhancing operational flexibility.

- Each model comes with a built-in thermal overload protector for the blower to ensure safe operation.

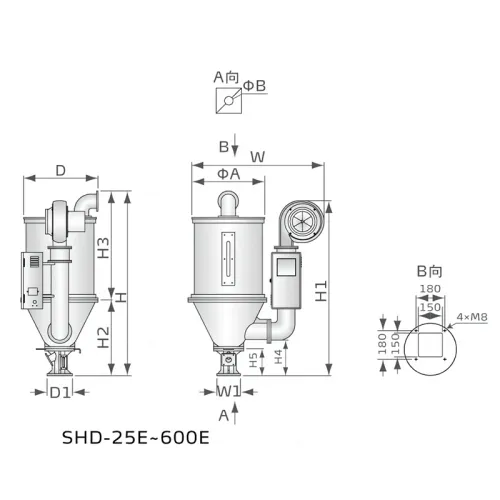

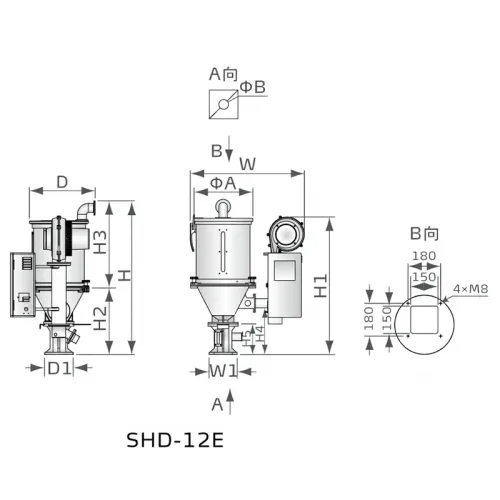

| Model SHD- | |||||||||||

| Drying heater (kW) | 2.2/3* | 3/3.3* | 3.9/4.2* | 4.2/4.8* | 6/6.6* | 6.6/7.2* | 12/15* | 15 | 18 | 19.5 | 21 |

| Blower (kW) | 0.1 | 0.17 | 0.17 | 0.17 | 0.2 | 0.2 | 0.35 | 0.35 | 0.45 | 0.45 | 1.03 |

| Loading capacity (kg) | 12 | 25 | 50 | 75 | 100 | 150 | 200 | 300 | 400 | 500 | 600 |

| H(mm) | 801 | 989 | 1112 | 1247 | 1316 | 1636 | 1852 | 2272 | 1933 | 2383 | 2174 |

| H1(mm) | 676 | 878 | 924 | 937 | 1151 | 1151 | 1573 | 1573 | 1609 | 1609 | 2054 |

| H2(mm) | 321 | 396 | 452 | 463 | 536 | 536 | 634 | 634 | 713 | 713 | 821 |

| H3(mm) | 480 | 593 | 660 | 784 | 780 | 1101 | 1218 | 1638 | 1220 | 1670 | 1354 |

| H4(mm) | 165 | 196 | 204 | 213 | 255 | 255 | 287 | 287 | 287 | 287 | 344 |

| H5(mm) | 107 | 150 | 150 | 150 | 173 | 173 | 194 | 194 | 205 | 205 | 245 |

| W(mm) | 646 | 728 | 787 | 874 | 996 | 996 | 1183 | 1183 | 1339 | 1339 | 1510 |

| D(mm) | 342 | 413 | 508 | 555 | 627 | 627 | 753 | 753 | 893 | 893 | 1033 |

| D1(mm) | 108 | 158 | 158 | 158 | 177 | 177 | 230 | 230 | 280 | 280 | 280 |

| Wl(mm) | 108 | 148 | 148 | 148 | 177 | 177 | 230 | 230 | 280 | 280 | 280 |

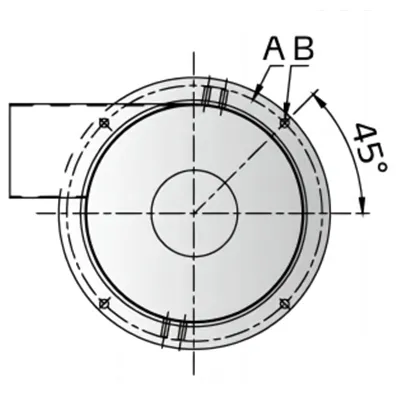

| ⌀A(mm) | 327 | 383 | 478 | 535 | 602 | 602 | 745 | 745 | 897 | 897 | 1050 |

| ⌀B(mm) | 42 | 53 | 53 | 53 | 81 | 81 | 110 | 110 | 116 | 116 | 130 |

| Weight (kg) | 23 | 25 | 37 | 39 | 55 | 56 | 113 | 116 | 132 | 134 | 205 |

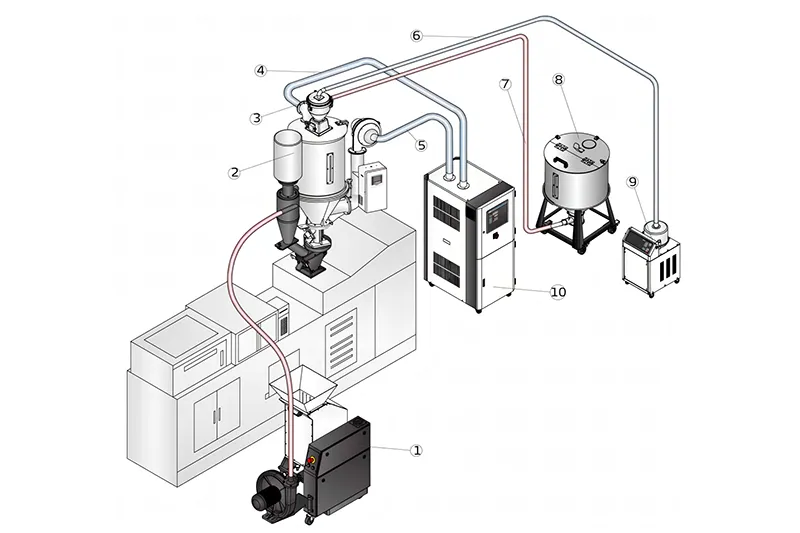

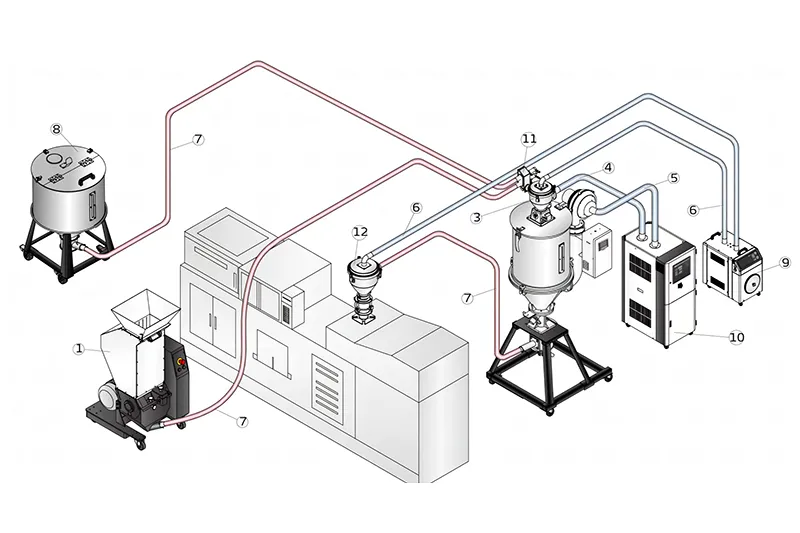

- Low-speed granulator

- 30-second quick recycling system

- Vacuum hopper

- Circulating air system

- Dehumidified air system

- Vacuum pipe

- Material pipe

- Material storage tank

- Vacuum hopper loader

- Honeycomb dehumidifier

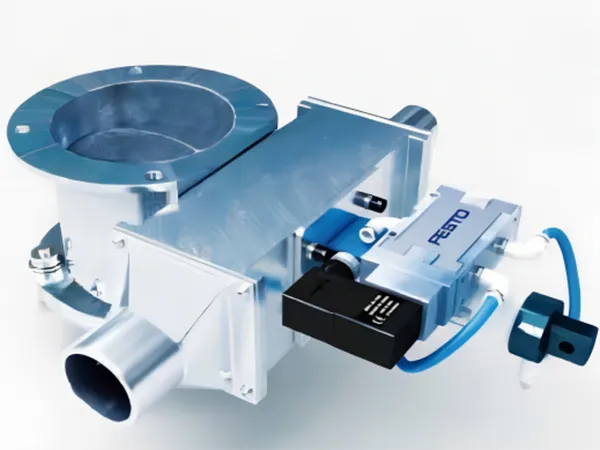

- Dual material proportional valve

- Hopper with photoelectric sensor

- High temperature model (180°C)

- Magnetic base

- RS485 communication interface

- 24V microcomputer control

- Three-color warning light

- Intelligent energy-saving system

- Insulated hopper

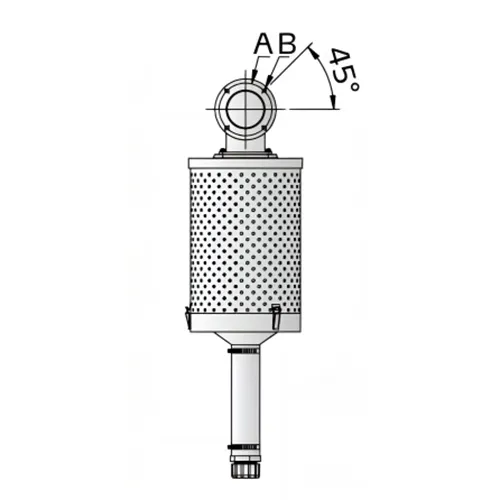

Hot Air Recycler

The hot air recycler is engineered to integrate with hopper dryers, facilitating a semi-enclosed circuit for hot air circulation. This drying system offers significant advantages:

- It recycles hot air within the system, effectively preventing significant increases in room temperature, which can be critical in maintaining operational efficiency.

- By maintaining cleaner air within the facility, it helps ensure the quality of the products manufactured, directly impacting final product standards.

- The system heats quickly and minimizes heat loss, offering substantial energy savings—up to 40% compared to traditional methods, making it both cost-effective and environmentally friendly.

Air Exhaust Filter

The air exhaust filter is designed to filter out dust air discharged from the dryer, ensuring the air remains clean with an efficiency of up to 99%. This filter not only prevents environmental contamination but also enhances workplace safety and compliance with air quality standards

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.