Sound-Proof Central Granulator

Plastic granulator for recycling wastes and rejected parts from plastic moulding machines

Sound-proof central granulators are tailored for efficient recycling of various plastic materials, including those from injection molding and blow molding processes, as well as general waste. This plastic auxiliary machine boasts an efficient design that facilitates easy operation and quick blade changes, enhancing overall workflow efficiency. The unique staggered rotating blade design enables effective material capture and granulation, minimizing energy loss and optimizing performance. Ideal for facilities seeking to enhance their sustainability efforts, it provides a powerful, yet quiet solution for recycling diverse plastic materials.

Sound-proof central granulators are tailored for efficient recycling of various plastic materials, including those from injection molding and blow molding processes, as well as general waste. This plastic auxiliary machine boasts an efficient design that facilitates easy operation and quick blade changes, enhancing overall workflow efficiency. The unique staggered rotating blade design enables effective material capture and granulation, minimizing energy loss and optimizing performance. Ideal for facilities seeking to enhance their sustainability efforts, it provides a powerful, yet quiet solution for recycling diverse plastic materials.

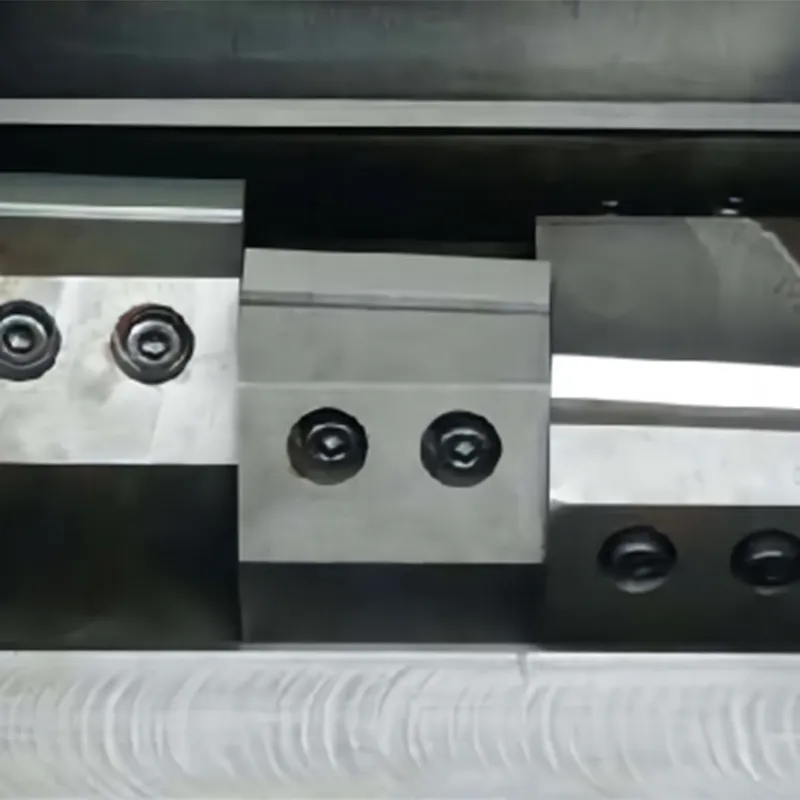

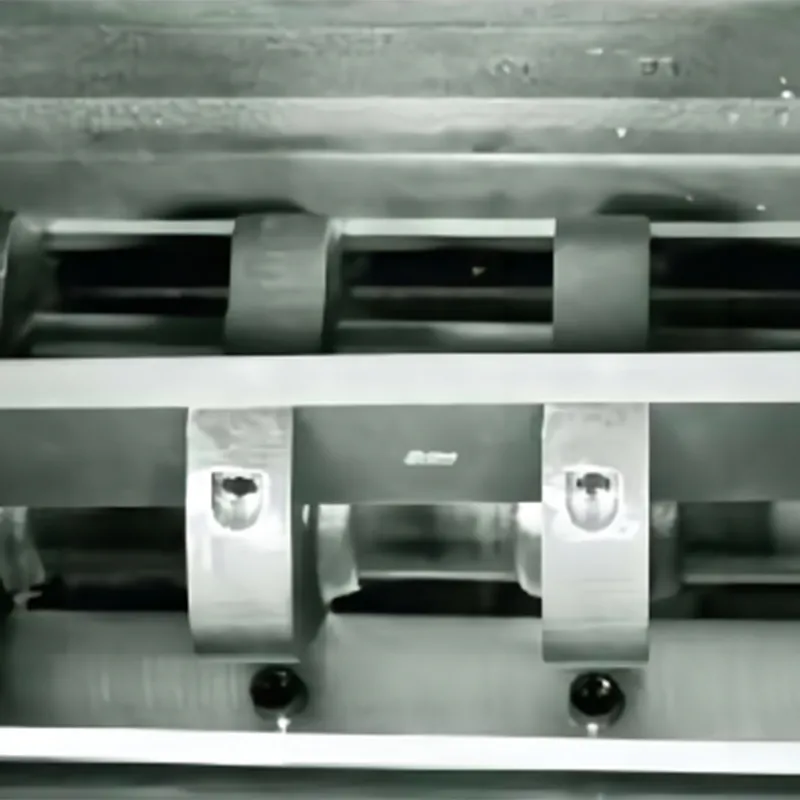

- Precision machined cutting chamber and cutting tools : Utilizing CNC machining, the cutting chambers are crafted with high precision, ensuring reliability. Our sound-proof central granulator features claw-type blades with a staggered structure, effectively dispersing impact loads and enhancing cutting efficiency. The design allows for easy blade replacement without the need for adjustments. The SG-30/36 central granulators utilize paddle blades with presetting knife jig, simplifying the installation and adjustment of blades externally, significantly reducing downtime for maintenance.

- Soundproofing design : The granulator body is enclosed in a fully soundproofed box with sound-absorbing materials placed at potential noise sources, effectively reducing noise during operation.

- Automatic feeding system : Equipped with an automated material transport system using a blower to facilitate air flow, which also helps cool the cutting chamber, significantly reducing the temperature inside and preventing material fusion.

- High-efficiency cutting motor: Incorporates an IE3 high-efficiency motor that reduces energy consumption while providing stable, safe, and reliable performance.

- Cutting chamber cooling device: Equipped with a water-cooling system at the backplate of the cutting chamber to effectively lower temperatures and prevent material from melting.

- Multiple safety protections: The electrical control system complies with European CE standards, including motor overload protection, short circuit protection, phase loss protection, and phase sequence detection, ensuring safe operation.

- Presetting knife jig: Equipped with an presetting knife jig that allows blade adjustments to be made externally, greatly simplifying blade maintenance and avoiding the complex process of internal adjustments.

| Motor power (kW) | 18.5 | |

| Rotating speed (rpm) | 540 | |

| Conveying blower power (kW) | 1.1 | |

| Blade material | SKD11 | |

| Quantity of fixed blade | 2×1 | |

| Quantity of rotating blade | 3×2 | |

| Cutting chamber (mm) | 360×500 | |

| Max. output capacity (kg/hr) | 620 | |

| Noise level dB(A) | 100-105 | |

| Diameter of screen mesh (mm) | ⌀10 mm | |

| Increased conveying blower power (kW) | 〇 (1.5) | |

| Dimensions | H(mm) | 2710-3155 |

| H1(mm) | 1520 | |

| H2(mm) | 360 | |

| H3(mm) | 1980 | |

| H4(mm) | 1240-1690 | |

| H5(mm) | 2100 | |

| H6(mm) | 780 | |

| W1(mm) | 1930 | |

| W2(mm) | 1900-2310 | |

| W3(mm) | 500 | |

| W4(mm) | 160×160 | |

| D(mm) | 1720 | |

| D1(mm) | 1250 | |

| D2(mm) | 4220 | |

| Weight (kg) | 1480 | |

| Notes: 1) "〇" stands for optional 2) SKD11 is JIS steel grade 3) The maximum output capacity depends on the diameter of screen mesh and composition of material 4) Noise level varies depending on different materials and motor types 5) All plastic materials should be crushed at normal temperature to avoid the blade from being sticked with materials 6) Power: 3Φ, 400VAC,50HZ | ||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.